Honk!

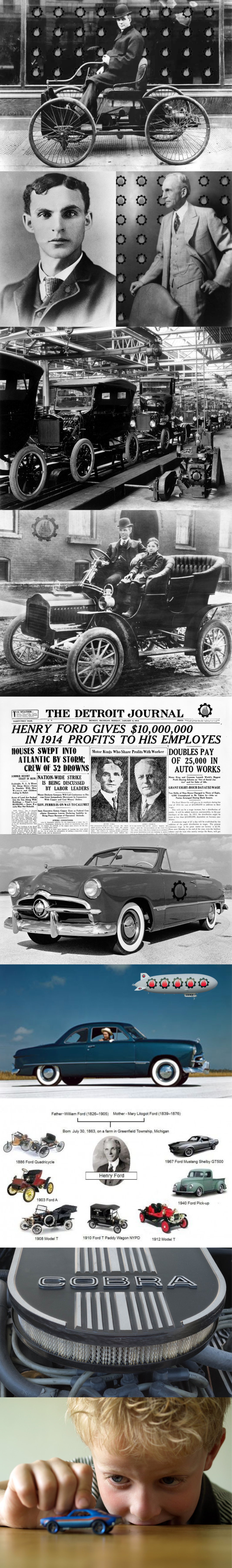

(top row) Henry Ford driving his Quadricycle, circa 1896; (row 2 left) Young, eager Henry Ford full of ideas and ambition; (row 2 right) A more seasoned Henry Ford with a lot of successes under his belt and ready for more challenges; (row 3) One of the Model T assembly lines; (row 4) Henry with his son Edsel in the rare Model F; (row 5) Making headlines in 1914–WOW!!!; (row 6) The 1949 Ford Convertible; (row 7) The 1949 Ford Coup; (row 8) Henry’s parents and his automotive legacy; (row 9) I‘m thinking Henry would liked to have seen this engine; (row 10) Maybe this young dreamer will go on to create the next generation of amazing vehicles.

Cars. So many to choose from. New, used, lease, hand me downs, rebuilt, and of course the new models, starting to hit showrooms. In my lifetime, I’ve owned all Ford vehicles, all of my married life I have had Ford conversion vans which were wonderful for traveling with our girls. Since they are all on their own I did downsize with my most recent vehicle….. I have an Expedition EL! Full disclosure they all gave me a bunch of grief about my “downsizing” choice until a dresser needed to be picked up, then a bunch of rocks then a queen head board, needless to say the list continues to grow! With all the fun and “buzz” about the new electric options – (check these babies out). I thought I’d go back a bit, and celebrate Mr. Ford’s introduction of the Model T, America’s first “road” car, debuted today back in 1908. Here’s the story, along with some interesting facts and great links for you motorheads. Enjoy!

- The Model T, sold by the Ford Motor Company from 1908 to 1927, was the earliest effort to make a car that most people could actually buy. Modern cars were first built in 1885 in Germany by Karl Benz, and the first American cars in Springfield, Massachusetts in 1893 by Charles and Frank Duryea. But just because they were available didn’t mean that ordinary people could afford them.

- The Model T was actually affordable and it became so popular at one point that a majority of Americans owned one, directly helping rural Americans become more connected with the rest of the country and leading to the numbered highway system. The manufacturing needs of the Model T went hand in hand with Ford’s revolutionary modernization of the manufacturing process.

- By day, Ford was chief engineer at Edison Illuminating Company of Detroit, but at night Henry Ford labored over a gasoline engine. He successfully tested one on Christmas Eve, 1893, with the help of his wife, Clara, taking a break from holiday cooking. The engine worked for 30 seconds, long enough to confirm for Ford that he was on the right track.

- Three years later, Ford developed the Quadcycle, a self-propelled vehicle. After two failed business ventures, the Ford Motor Company was born on June 16, 1903.

- Official Model T development began in January 1907, when Ford assembled a team comprised of engineer Childe Harold Wills, machinist C.J. Smith and draftsman Joseph Galamb in his small Detroit factory on Piquette Avenue. Between 1913 and 1927, Ford factories produced more than 15 million Model Ts.

- Released on October 1, 1908, the Ford Model T was a self-starting vehicle with a left-sided steering wheel, featuring an enclosed four-cylinder engine with a detachable cylinder head and a one-piece cylinder block. It also featured a generous ground clearance that could take the worst roads, which made it particularly enticing to rural drivers. The Model T was the first Ford with all its parts built by the company itself.

- Selling for $850, it was considered a reasonable value, though still slightly higher than the income of the average American worker. Ford’s goal was to continue lowering prices.

- After selling 10,607 Model Ts, Ford announced that the company would cease to sell the Model R or Model S cars, famously remarking that “Any customer can have a car painted any color that he wants so long as it is black.”

- Ford typically engineered publicity stunts to get his cars covered in British newspapers. In 1911, a Scottish car dealer proposed challenging his son Henry Alexander Jr. to drive a Model T to the summit of Ben Nevis in the Scottish Highlands, the highest mountain in the British Isles at 4,411 feet. The bet was that if he failed to reach the summit Alexander would lose his allowance.

- Starting at nearby Fort William, the Model T drove over rocks, across bogs and through snow on a five-day journey. The car ascended to the summit using a zig-zag driving pattern. After his descent, Alexander was greeted by a cheering crowd of hundreds, after which he made brake adjustments and drove the car back to his father’s dealership in Edinburgh. (Following the publicity, over 14,000 Model Ts were sold in the UK. It was the last time Ford felt a publicity stunt was necessary to sell his cars there).

- By 1913, a new 60-acre factory was built in Highland Park to churn out Model Ts. At the time it was considered to be the biggest factory in the world, and the number of Ford employees more than doubled. For this plant, Ford worked to improve the assembly line of the manufacturing process. On April 1 tests were run, an attempt to assemble a flywheel magneto for the Model T. This was the first moving assembly line ever, utilizing conveyor belts inspired by Chicago meatpacking plants. The factory was divided into sections, each assembling a single part of the car in an incremental building process. The Highland Park factory eventually featured 500 of these departments in its assembly line.

- . In six months, the time to build a Model T was reduced from nine hours and fifty-four minutes for one motor to five hours and fifty-six minutes.

- The nickname “Tin Lizzie” is often applied to the Model T, though its origin is unknown. One tradition claims Lizzie was a generic name given to horses and was passed onto the Model T. Later, a San Antonio car dealer complained to the factory about ill-fitting doors on the car and asked if cars could be shipped without doors but include a tool kit for purchasers to cut their own, reminiscent of a tin can opener.

- Another claim says that during a 1922 race at Pikes Peak, Colorado, participant Noel Bullock named his Model T “Old Liz,” but its unkempt state made people compare it to a tin can, earning it the “Tin Lizzie” moniker. Unexpectedly, Bullock’s car won, and the nickname stuck to all Model Ts.

- Competition arose in the mid-1920s giving consumers about 10 times more choices of touring car models than a decade earlier. The Model T tried to compete, but sales dropped, and Ford’s “T” became considered old fashioned and was the frequent butt of popular jokes.

- After much hesitation by Ford, it was announced in 1927 that Model Ts would no longer be manufactured. The new Ford called Model A debuted in December after having to scrap 40 thousand tools that could only be used to build Model Ts.

- When we think of Henry Ford, most of us think about the famous Model T Ford from the early 20th century. Despite his constant association with his brand, Ford was a man of many talents who embraced a passion for science and development. These unexpected facts highlight his inner developer and how he helped the auto industry and beyond.

Some “fun to know” trivia …

1. Henry Ford made watches – Henry Ford was destined to be an innovator, and he displayed this after being gifted a pocket watch. Automobiles were not the first products of Ford’s engineering. As a young man, he enjoyed crafting and building watches for his loved ones and friends. If the Michigan native did not have the proper tool for building a watch, he’d just make what he needed.

2. He kept the lights on for a whole city – After his early innovation with watches, Ford moved to brighten the city of Detroit by working at the Edison Illuminating Company. He worked up to Chief Engineer and was ultimately responsible for keeping the lights on in Detroit. This position encouraged his creative mind and served as his final inspiration to move forward with his gasoline automobile.

3. Ford created mass production – Ford not only created the Model T Ford for Americans, but he founded the idea of mass production for affordability. Making mass amounts of Model Ts elevated the quality of life for many Americans. These days, mass production is found in nearly every industry.

4. Ford created one of the first assembly lines – In 1913, Ford was responsible for the first assembly line that consistently moved. This became a trademark system in manufacturing facilities across the globe. While it was not the first assembly line, it was the first that continuously moved by workers and established an efficiency unmatched at the time – even today, think Chipotle …

5. He has more than 160 patents – By the time of his death in 1947, Ford had established over 160 patents of products and designs. In most of his designs, Ford was striving to create products that would make working smarter and improve the quality of work.

6. Ford was full of surprises – There are depths to Ford that only those closest to him knew. By creating the Model T Ford, he not only encouraged car-buying for Americans but also innovative manufacturing. While he did become one of the richest Americans of his time, Ford’s goal was to create efficient work for Americans and generate a richer economy overall.

7. The king of charcoal – An avid outdoorsman and early environmentalist, Henry Ford found a way to solve two problems…waste from his sawmill and cooking fuel source for camping trips…with the invention of Kingsford Charcoal. By 1919, his company was producing a million cars a year. About 100 board feet of wood went into each car…in the steering wheel, dashboard, and other parts. Ford wanted his own source of wood so he wasn’t at the mercy of other suppliers and inconsistent costs. So, he contacted his cousin’s husband, Edward G. Kingsford, a Michigan real estate agent, to help him find and purchase timberland. He found just want he needed in Iron Mountain, Michigan and built a sawmill there to cut the wood for shipping to Detroit. Ford, a nature-lover, was also an early environmentalist and lived by the motto, “reduce, reuse, and recycle.” He was bothered by the wasted wood at his Iron Mountain sawmill. Ford hated to see the resources going unused and sought a way to make use of the byproducts of his sawmill so he pressed it into lumps held together by tar and cornstarch, as a quick and easy way to start cooking a fire. He named these lumps charcoal briquettes and built a briquette manufacturing facility next door to the sawmill. He sold the briquettes in picnic packs and promoted the link between owning an automobile and experiencing the great outdoors. Genius!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

DO YOU LIKE CONTESTS?

Me, too.

As you may know the Kowalski Heat Treating logo finds its way

into the visuals of my Friday posts.

I. Love. My. Logo.

One week there could be three logos.

The next week there could be 15 logos.

And sometimes the logo is very small or just a partial logo showing.

But there are always logos in some of the pictures.

So, I challenge you, my beloved readers, to count them and send me a

quick email with the total number of logos in the Friday post.

On the following Tuesday I’ll pick a winner from the correct answers

and send that lucky person some great KHT swag.

So, start counting and good luck!

Oh, and the logos at the very top header don’t count.

Got it? Good. :-))))

Have fun!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::