Play Well

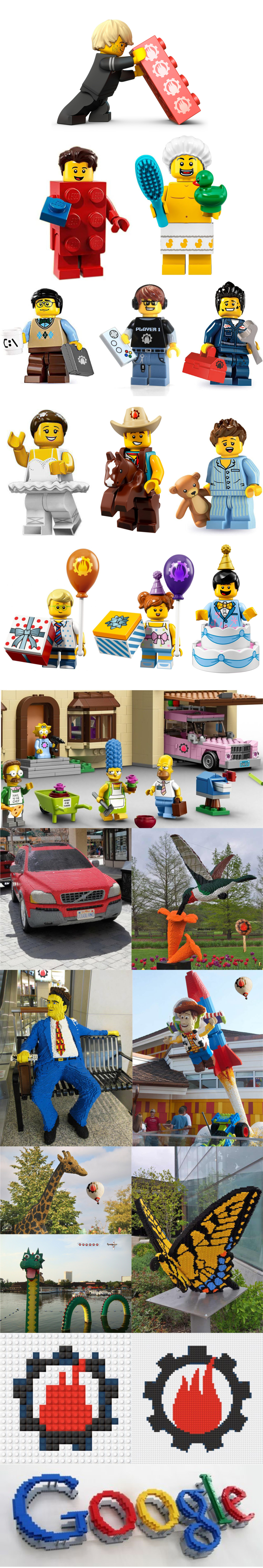

Legos…are they for kids? Sure. But adults around the world are building amazing sculptures with them. And the Lego global manufacturing processes and distribution system is nothing short of astonishing. Check it out. And if you have a Lego build you’re proud of, send me a picture. I’d love to see it. The one I’m proud of is my logo made from Legos near the bottom above. The one on the left is 20×20 single blocks. The one on the right is 70×70. Cool, huh?? :)))) If you want to see more Lego creations, kits and fun, Google it.

In these cold, wintery days, I find myself more interested in staying inside and relaxing (especially after shoveling) – staying warm, reading a book, or playing a game. Games and toys are a big part of the Kowalski traditions, especially around the holidays when we’re all together. Since Jackie and I are blessed to have the grandkids close by we have been able to introduce them to many of the wonderful toys our girls grew up with. Jackie pulled out our collection of Legos this past weekend. I must say we do have a significant collection! After washing them all after years in storage… I got thinking about how cool, and simple, these toys are and then of course took to the “net” and did some digging. Lego, was founded in the workshop of Ole Kirk Christiansen (1891–1958), a carpenter from Denmark, who began his career making wooden toys. In 1934, his company came to be called “Lego”, derived from the Danish phrase leg godt [lɑjˀ ˈkʌt], which means “play well”. In the late 40’s Lego expanded from wooden toys to producing plastic toys and in ‘49 Lego began producing, among other new products, an early version of the now familiar interlocking bricks, calling them “Automatic Binding Bricks”. Fast forward to today, and Lego has become a global brand (ranks in top 5 awareness) manufacturing “bricks” by the billions. For my manufacturing and engineering buds out there, be sure to watch the production videos below … talk about PIA (pain in the @%$) Jobs! – the inventory, quality control, packaging and distribution logistics are absolutely remarkable. I have to say the level of automation / technology in their facilities make me a little jealous! Below is some history and trivia on that first simple patent (1/28/58) for little stackable bricks. Enjoy! And thanks to YouTube, Wikipedia and Lego for the info.

VIDEO: Bricks in the making

VIDEO: Making the little people

VIDEO: Technic in action

***Caution: these videos are amazing – may impact your afternoon productivity!!

The Lego Group began in the workshop of Ole Kirk Christiansen (1891–1958), a carpenter from Billund, Denmark, who began making wooden toys in 1932. In 1934, his company came to be called “Lego”, derived from the Danish phrase leg godt [lɑjˀ ˈkʌt], which means “play well”.In 1947, Lego expanded to begin producing plastic toys. (FYI – plural for Lego … Lego)

In 1949 Lego began producing, among other new products, an early version of the now familiar interlocking bricks, calling them “Automatic Binding Bricks”. These bricks were based on the Kiddicraft Self-Locking Bricks, which had been patented in the United Kingdom in 1939 and released in 1947 (oops! bad decision). Lego had received a sample of the Kiddicraft bricks from the supplier of an injection-molding machine that it purchased – and purchased, and purchased – (see videos!)

The Lego Group’s motto is “only the best is good enough” (Danish: det bedste er ikke for godt, literally “the best isn’t excessively good”). This motto, which is still used today, was created by Christiansen to encourage his employees never to skimp on quality, a value he believed in strongly.

By 1951 plastic toys accounted for half of the Lego company’s output, even though the Danish trade magazine Legetøjs-Tidende (“Toy Times”), visiting the Lego factory in Billund in the early 1950s, felt that plastic would never be able to replace traditional wooden toys (oops! bad insight).

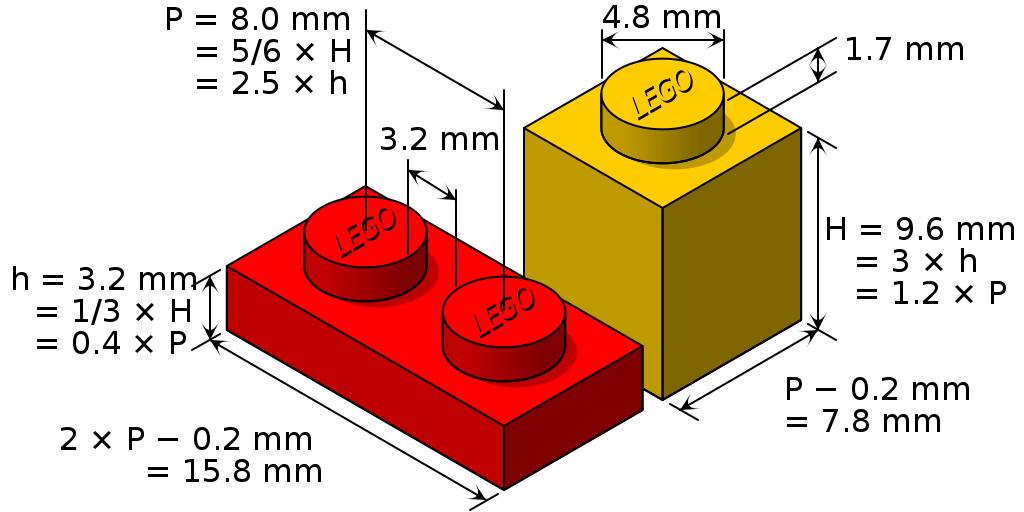

By 1954, Christiansen’s son, Godtfred, (I love it when sons’/family step in) had become the junior managing director of the Lego Group. It was his conversation with an overseas buyer that led to the idea of a toy system. Godtfred saw the immense potential in Lego bricks to become a system for creative play, but the bricks still had some problems from a technical standpoint: their locking ability was limited, and they were not versatile. In 1958, the modern brick design was developed; it took five years to find the right material for it, ABS (acrylonitrile butadiene styrene) polymer. A patent application for the modern Lego brick design was filed in Denmark on January 28, 1958, and in various other countries in the subsequent few years.

Lego pieces of all varieties constitute a universal system. Despite variation in the design and the purposes of individual pieces over the years, each piece remains compatible in some way with existing pieces. Lego bricks from 1958 still interlock with those made in the current time, and Lego sets for young children are compatible with those made for teenagers. Six bricks of 2 × 4 studs can be combined in 915,103,765 ways (I knew that – just do the math silly!).

The Lego Group’s Duplo product line was introduced in 1969 and is a range of simple blocks whose lengths measure twice the width, height, and depth of standard Lego blocks and are aimed towards younger children. (Yep, we have mostly these in the house).

In 1978, Lego produced the first minifigures, which have since become a staple in most sets.

In May 2013, the largest model ever created was displayed in New York City and was made of over 5 million bricks; a 1:1 scale model of an X-wing fighter. Other records include a 34-metre (112 ft) tower and a 4 km (2.5 mi) railway. See top 20 World Records Here – unreal!!

In February 2015, Lego replaced Ferrari as the “world’s most powerful brand.”

Lego’s popularity is demonstrated by its wide representation and usage in many forms of cultural works, including books, film & TV and artwork, theme parks, retail stores (over 700!), books, apparel and more. It has even been used in the classroom as a teaching tool.

Each Lego piece must be manufactured to an exacting degree of precision. When two pieces are engaged they must fit firmly, yet be easily disassembled. The machines that manufacture Lego bricks have tolerances as small as 10 micrometers.

The average development period for a new product is around twelve months, split into three stages. The first stage is to identify market trends and developments. The second stage is the design and development of the product based upon the results of the first stage.. These prototypes are presented to the entire project team for comment and for testing by parents and children during the “validation” process.

In 1998, Lego bricks were one of the original inductees into the National Toy Hall of Fame at The Strong in Rochester, New York.

Lego factories recycle all but about 1 percent of their plastic waste from the manufacturing process. If the plastic cannot be re-used in Lego bricks, it is processed and sold on to industries that can make use of it. Lego has a self-imposed 2030 deadline to find a more eco-friendly alternative to the ABS plastic it currently uses in its bricks.

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

DO YOU LIKE CONTESTS?

Me, too.

As you may know the Kowalski Heat Treating logo finds its way

into the visuals of my Friday posts.

I. Love. My. Logo.

One week there could be three logos.

The next week there could be 15 logos.

And sometimes the logo is very small or just a partial logo showing.

But there are always logos in some of the pictures.

So, I challenge you, my beloved readers, to count them and send me a

quick email with the total number of logos in the Friday post.

On the following Tuesday I’ll pick a winner from the correct answers

and send that lucky person some great KHT swag.

So, start counting and good luck!

Oh, and the logos at the very top header don’t count.

Got it? Good. :-))))

Have fun!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::