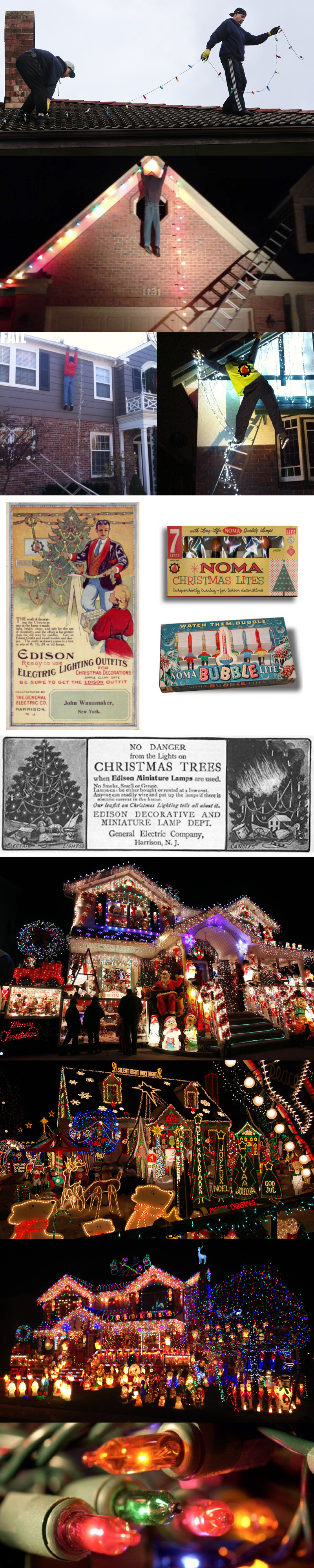

First You Get the Ladder…

The fun of the season. Getting the house all lit up and glowing. It can be hazardous as those few pictures suggest so be careful out there. Below those images are a couple of really old ads for lights. That black & white ad is selling the safety of electric lights vs candles which may burn down your house. I’m sold. And a couple of old boxes of lights. Remember those bubble lights? I thought those were the greatest. Still do. Then there are the photos of some way over the top lighting displays. Love it!!!

Yep – it’s that time of year, my annual ritual of lighting up the house for the holidays. Like you, I’m torn – my logical brain says I should take advantage of the warmer weather and hang the lights before Thanksgiving, cleaning out the gutters and avoiding the cold. But my “do other chores or just watch football” brain says – oh, you can wait – and then I find myself outside in the freezing wind, shaking on the ladder as I hang half frozen bulbs across the gutters … To be honest, my lovely wife Jackie helps me decide … 🙂 Now, although I love how our home looks all lit up, I have reached a point where Jackie and I have agreed that I am not allowed to be climbing, crawling, kneeling, hanging on the roof any longer. For some reason the downsides of falling off outweigh the upsides of hanging lights all over the roof-windows, etc! With this in mind, I started to think about the design and manufacturing marvel those tiny little bulbs are. Talk about a PIA (Pain in the @%$) Job – figuring out an efficient, low cost way to manufacture billions of bulbs to meet our ongoing desire to light up our homes both inside and out. Here’s some cool history and info on the manufacturing of holiday lights. Thanks to the genius of Edison, and all those engineers who machined, (heat treated YEA!!) built the machines and make them go. Enjoy. And special thanks to howmade.com and Business Insider for the videos.

- Festivals in a number of ancient civilizations were celebrated with lights; any and all of these may have been the inspiration for the lights we use to decorate Christmas trees and the exteriors of homes.

- The Druids in both France and England believed that oak trees were sacred, and they ornamented them with candles and fruit in honor of their gods of light and harvest. The ancient Roman festival of Saturnalia included trees decorated with candles and small gifts. The worship of trees as the homes of spirits and gods may have led to the Christmas tree tradition and that tradition has long been accompanied by the companion custom of decking the tree with brilliant lights evoking stars, jewels, sparkling ice, and holiday cheer.

- From the beginnings of Christianity to about 1500, trees were sometimes decorated outdoors, but they were not brought into homes. One legend has it that Martin Luther (1483-1546), the father of Protestantism, was walking through an evergreen forest on Christmas Eve. The beauty of the stars sparkling through the trees touched him, and he took a small tree home and put candles on its branches to recreate the effect for his family.

- Similarly, German settlers brought the Christmas tree to America where the first tree was displayed in Pennsylvania in 1851. Candles were attached to the boughs of the trees with increasingly extravagant candle-holders, some with colored glass that made the lights appear colored. Of course, the practice of using candles was hazardous; many fire brigades were called to extinguish fires started by candles that had ignited the trees or the long hair or dresses of the ladies. Candles on trees were lit for several minutes only and sometimes only on Christmas Eve or Christmas Day; the custom of lighting trees for extended periods of time had to wait until the invention of the electric light bulb.

- The first electric lights for Christmas debuted only three years after Thomas Alva Edison invented the lightbulb in 1879. Edward Johnson, a resident of New York and a colleague of Edison’s, was the first to have an electrically lighted Christmas tree in his home in 1882.

- The tiny bulbs were hand blown and the lights were hand-wired to make this event possible, but it opened an avenue for Edison’s electric company that produced miniature, decorative bulbs for chandeliers and other uses from its earliest days. Electric lights appeared on the White House Christmas tree in 1895 when Grover Cleveland was President.

- General Electric (GE) bought the rights to light-bulb production from Edison in 1890, but GE initially only made porcelain light bulbs. To light a tree, the family had to hire a “wireman” who cut lengths of rubber-coated wire, stripped the ends of the wires, fastened them to sockets with brass screws, fitted a larger socket to a power outlet or light fixture, and completed assembly of a string of lights. This was too expensive and impractical for the average family. This was a major PIA (Pain in the @%$) job!

- In 1903, the Ever-Ready Company of New York recognized an opportunity and began manufacturing festoons of 28 lights. By 1907, Ever-Ready was making standard sets of eight series-wired lights; by connecting the sets or outfits, longer strings of lights could be made.

- Ever-Ready did not have a patent on its series-wired strings of lights, and this basic wiring system was adapted by many other small companies. These sets were not always safe, and episodes of tree fires raised public alarm.

- In 1921, Underwriters’ Laboratories (UL) established the first safety requirements for Christmas lights. A number of light manufacturers merged in 1927 to form the National Outfit Manufacturers Association (NOMA), which went on to dominate the Christmas light business, with GE and Westinghouse as the leading bulb makers. Also in 1927, GE introduced parallel wiring that permitted light bulbs to keep glowing when one on the string burned out.

- Bulb shapes also evolved. In 1909, the Kremenetzky Electric Company of Vienna, Austria, began making miniature bulbs in the shapes of animals, birds, flowers, and fruit. Companies in the United States, Japan, and Germany also made figurative bulbs, but Kremenetzky consistently made the most beautiful glass that was hand-painted.

- World War I ended the influx of Austrian lights. GE made machine-blown shapes beginning in 1919, and the Japanese light-bulb industry, then in its infancy, began filling the void left by the Austrians. The Japanese techniques continued to improve and were quite sophisticated by 1930, but this trade ended with World War II.

- NOMA started to make tiny lampshades with Disney figures on them to fit over standard miniature bulbs in 1936. The most spectacular miniature bulb success was the bubble light. Carl Otis invented it in the late 1930s, but World War II also interrupted this development. Bubble lights were finally introduced in 1945, peaked in popularity in the mid-1950s, and declined by the mid 1960s. So-called midget lights, midget twinkle lights, or miniature Italian lights began arriving from Europe in the 1970s and became the best sellers of all time in the Christmas tree light business.

- Today, holiday lights are made of three sets of materials. The strings are composed of 22-gauge copper wire that is coated in green or white polyvinyl chloride (PVC) plastic. Specialized manufacturers supply the wire on spools that hold 10,000 ft of wire. Two plugs begin and end each set of lights, and they are made of injection-molded plastic. The lights are held in lamp holders that are also injection-molded plastic and contain copper metal contacts.

- The second set of materials goes into the making of light bulbs. The bulbs are made of blown glass, metal filaments, metal contact wires, and plastic bases. Bulbs are made in clear glass to produce white light, or they are painted to shine in assorted colors.

- Finally, the finished sets of lights require packing materials. These include a molded plastic tray, a folded cardboard display box, and shipping cartons that hold multiple sets of boxed lights. The shipping cartons are made of corrugated cardboard. Each set is also packed with adhesive-backed safety labels and paper instruction and information sheets. All of the paper goods are made by outside suppliers and are produced from recyclable materials.

- The basic design for holiday lights consists of a tried-and-true string of green plastic-covered wires with clear or colored light bulbs. Design aspects include the number of lights on the string (in multiples of 25 with 25, 50, 100, or 125 bulbs) and whether the string contains only clear bulbs, bulbs of a single color, or assorted colors of lights.

- Green wires were made originally to blend in with the green branches of evergreens, either as indoor Christmas trees or outdoor shrubs. The tiny lights are used for many other holidays and for garden displays, so strings with white wires are made for other decorating uses. Plastic covers for the lights are also designed with Christmas and childhood themes as well as an extraordinary range for party decorating from aquarium fish to chili peppers.

- The newest designs to take the decorating market by storm are nets of lights that can be spread over shrubs to save time in decorating, and icicle lights that look like long white icicles hanging from house eaves. Fiber-optic lights also became available in the 1990s; they are basic strings of wire and light bulbs, but each bulb is the source of light that passes through clusters of fiber-optic wire held in plastic covers that clip onto the bulb. Usually, they resemble flowers or other designs that take advantage of the cluster-like display of optic wires.

The Manufacturing Process – watch video or read the steps HERE

Leave a Reply

Want to join the discussion?Feel free to contribute!