HARDENING OF ALLOY AND TOOL STEELS FOR IMPROVED PERFORMANCE

At Kowalski Heat Treating (khtheat.com), we’re constantly working on behalf of our customers to achieve the proper balance of strength, durability and end performance when processing alloy and tool steels. This heat treatment process consists of heating and cooling these steels to move atoms to an atomic state called martensite.

The atomic arrangement of steels vary depending on the structure or phase it is in. Controlled heat treatment changes the arrangement of these atoms resulting in a desired hardness and mechanical properties specified by our customers. Often we customize this process to enhance tool life and durability.

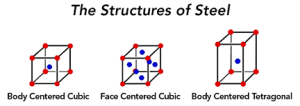

“Tool steels are typically annealed after rolling or forming to make them suitable for machining and other operations, a process which consists of heating the steel slowly and uniformly to a temperature above the transformation range,” says Dave Lorenz, VP of Operations / Metallurgist at Kowalski Heat Treating. “The transformation range is the temperature at which the steel starts to form austenite, usually around 1350°F (the annealing temperature is 1600-1700°F). A slow cooling rate (25 – 40°F/hour maximum) from this temperature enables the alloys, in combination with the iron atoms, to form uniformly dispersed spheroidized carbides in a matrix of ferrite. This ferrite structure is a body-centered cubic structure (see graphic), typically the condition in which we receive steel tool grades unless they are pre-hardened by the customer.”

“To achieve the next phase, the tool steel is hardened by bringing the material up to its austenitizing temperature, which will range from 1500 – 2250°F depending on the grade,” said Dave. “Upon going through this transformation temperature range, the structure changes again – from ferrite to austenite. This austenite atomic structure is a face-centered cubic (see graphic) – a high temperature phase only formed by heating the tool steel to the appropriate temperature. Austenite is non-magnetic and is slightly denser than ferrite, causing the steel to shrink slightly when at this stage in heat treatment.”

“Upon cooling or quenching from the austenitizing temperature, the steel is transformed once again into a new atomic arrangement called martensite. The steel must be cooled fast enough to keep the dissolved alloy content in the matrix of the steel. The martensite is in the form of a body centered tetragonal structure (see chart) – the desired structure that most of our tool steels are in to achieve high hardness and strength properties. This arrangement of atoms is less dense which results in an overall growth after the quench and subsequent tempers.”

Once completed, the tool steel is shipped back to customers to be machined or sharpened for superior performance.

For more information on tool steel processing, contact Kowalski Heat Treating (khtheat.com) – the leader in distortion sensitive thermal processing, celebrating 40 years of excellence and customer service.