Transformed

Technology. The future is here. And the future is coming. So, hang on to your hat, baby!!!!!!!!!!

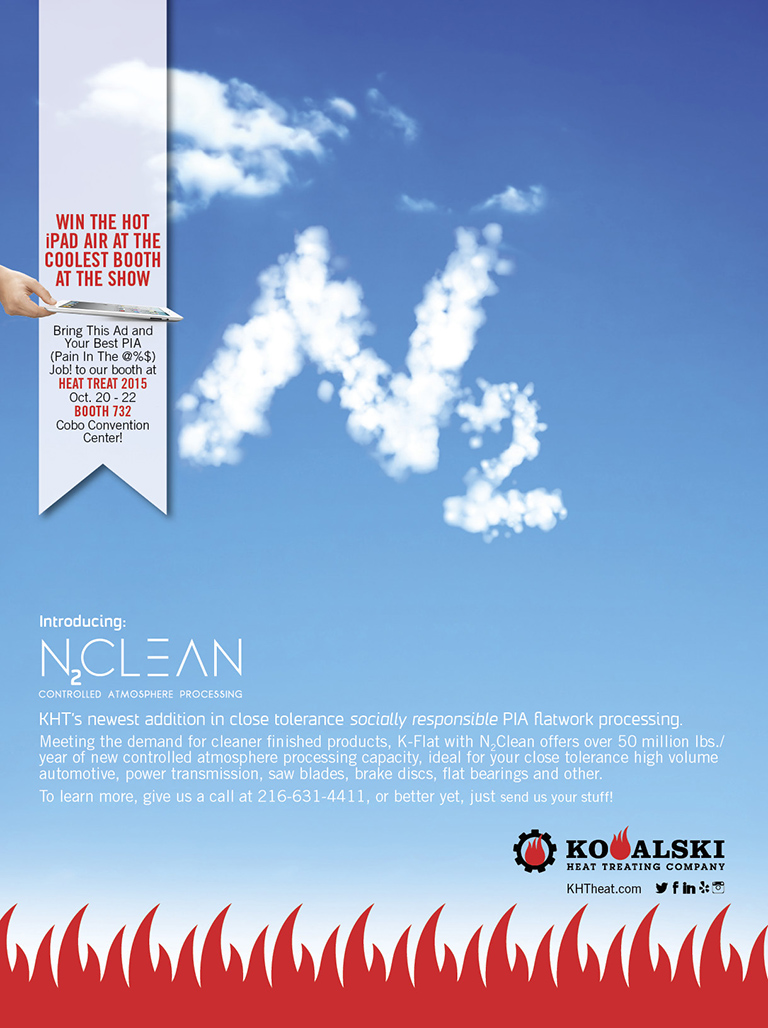

There’s no question that technology has profoundly changed the way we live — how we pay for groceries, watch our favorite shows, browse restaurant menus, communicate and so much more. While these are all seemingly ordinary interactions in modern day, they are woven with extraordinary innovation, transforming how we interact and make decisions. It’s easy to forget the level of technology involved in simply “tapping” a card to pay a bill or uploading a photo to social media. Pretty amazing, right? I get such a kick out of new inventions and new ideas. My gang here at KHT really goes out of their way to solve problems (you know, your PIA (Pain in the @%$) Jobs! One of our favorite solutions is to 3D print prototype fixtures to better rack parts before we treat them. It’s concepts to completion in a matter of hours. It is amazing how designs don’t always translate into success, with actual fixtures our team can see first hand! Below, is a list of several technological inventions that have transformed many of our day-to-day lives. And with all the excitement about AI, it’s tough to guess just what’s in the pipeline. Much of this technology has incredible benefits for us, we just need to be cautious! Thanks to nicenews.com and wallstreetjournal.com for the info. Enjoy!

Personalized Algorithms

Looking for a new show to watch? Netflix has a rec for that based on your personal preferences. According to Netflix, “Recommendation algorithms are at the core of the Netflix product. We continually seek to improve them by advancing the state-of-the-art in the field. We do this by using the data about what content our members watch and enjoy along with how they interact with our service to get better at figuring out what the next great movie or TV show for them will be.” It’s reported that people discover more than 80% of the shows they watch on the streaming platform through this recommendation system, which speaks to the power of personalization. The system works by using “machine learning and algorithms to help break viewers’ preconceived notions and find shows that they might not have initially chosen.” The goal: Keep finding people new things to watch.

Contactless Payments

Changing the way we make purchases, contactless payments allow for data transfer and wireless communication between devices. Nerd Wallet explains, “Near-field communication, or NFC, technology is used for contactless payments and allows wireless communication between two devices — a contactless card and a card reader, for example. Technology, like NFC, that uses radio frequency identification, or RFID, has been around for decades.” RFID “sends information between a tag to a scanner. The scanner, or reader, emits radio waves that pick up signals from nearby items with RFID tags, which also send out radio waves,” per the outlet. “With its ability to store and send huge amounts of data, RFID technology has been implemented in a number of sectors, including health care and the military, in a variety of applications.” This type of technology allows for “tap” payments, in which a card or device is held above a reader to make a transaction-now used in 79% of worldwide transactions.

QR Codes

Invented in 1994, Quick Response, or QR, codes were initially designed by a Japanese company to track automobile parts moving through the assembly process. Fast forward to 2020, and these scannable bar codes boomed in popularity. In a 2021 CNBC article, it was reported that Bitly, a link management service, saw a 750% increase in QR code downloads over the prior year and a half. Today, QR codes are seen everywhere, from menus and boarding passes to coupons and business cards. And growing in popularity are QR code tattoos, with scans of the body ink taking viewers to songs, images, and more. In my neighborhood, a local candidate put one on his yard signs, providing a fast link to his info page. Brilliant!

Facial Recognition

Though facial recognition technology has its roots in the 1960s, the software was popularized in 2010 when Facebook started using it to identify faces in user-uploaded photos. In the decade since, the social media platform has scaled back its usage of the system, but the technology is increasingly being employed for good in other ways. These include securing access to phones, laptops, and passports; finding lost pets; aiding in solving crimes; and going through airport security. While the technology has its drawbacks, the Pew Research Center reported the public is “more likely to see facial recognition use by police as good, rather than bad for society.” Here in Cleveland, they are using it at Browns Stadium for beer purchasing … not sure that’s a good idea. This is one technology we all have to be careful with.

Payment Sharing Apps

A hero for group dinners, Venmo started in 2009 as a way to digitally pay friends. More than a decade later, it’s still known to be one of the best apps for splitting bills and sending money without a fee. It’s so ubiquitous that there are even Venmo etiquette rules! I use it often to send or receive money from my girls, or pay my golf debts – not that I have any … PayPal — founded in 1998 — remains the most popular payment sharing platform, used by 57% of U.S. adults, according to Pew Research Center.

Statistical Machine Translation

In 2006, Google launched Google Translate, which utilizes statistical machine translation: an approach that uses “large volumes of bilingual data to find the most probable translation for a given input.” While the service doesn’t always give ideal translations for the correct context, it is useful for travelers trying to read a menu or anyone seeking to better communicate with someone who speaks another language. It has steadily expanded to over 100 languages and has upgraded its features with additions like instant camera translations. And the tool reached a major milestone in 2021, marking 1 billion installs on Android devices.

Global Positioning System

Chances are you use Google Maps, Waze, or a similar app to get from point A to point B, and you have the Global Positioning System, or GPS, to thank for that. Although GPS has its origins in the 1970s and was initially used for military purposes (my friends uncle worked at Bell Labs and used it for guidance systems), it went mainstream in 2007 — in cars, cell phones, and other gadgets. GPS is “a space-based radio-navigation system consisting of a constellation of satellites broadcasting navigation signals and a network of ground stations and satellite control stations used for monitoring and control,” per the Federal Aviation Administration. “Currently 31 GPS satellites orbit the Earth at an altitude of approximately 11,000 miles providing users with accurate information on position, velocity, and time anywhere in the world and in all weather conditions.”

Zoom and Video-Calling Services

Practically synonymous with video chat, Zoom has changed the way many of us work and communicate with loved ones. The platform facilitates remote work, meetings, and catchups from afar by allowing people to connect virtually in calls of up to 300 participants. While it may seem like the platform became an overnight success in 2020 at the height of the COVID-19 pandemic, the platform was actually founded in 2011. Today, there is countless competition in the video conferencing space, but Zoom continues to be a top choice for its functionality and popularity.

ChatBots

We all are amazed at chat.ai. Likewise, an early-stage startup backed by Gates’s private office, is launching a chatbot that offers users personalized recommendations for books, movies, TV shows and podcasts. The chatbot, called Pix, runs on Open AI’s natural-language processing technology and will learn users’ preferences over time. It will be free to users. The Gates-backed startup plans to use its 600 million consumer data points to distinguish its media-recommendation platform from the one-size-fits-all chatbots that are already available. Unlike the recommendation software available within streaming services, Pix will suggest content across platforms to users who text, email or ask it questions via its app. Watch it explode!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

DO YOU LIKE CONTESTS?

Me, too.

As you may know the Kowalski Heat Treating logo finds its way

into the visuals of my Friday posts.

I. Love. My. Logo.

One week there could be three logos.

The next week there could be 15 logos.

And sometimes the logo is very small or just a partial logo showing.

But there are always logos in some of the pictures.

So, I challenge you, my beloved readers, to count them and send me a

quick email with the total number of logos in the Friday post.

On the following Tuesday I’ll pick a winner from the correct answers

and send that lucky person some great KHT swag.

So, start counting and good luck!

Oh, and the logos at the very top header don’t count.

Got it? Good. :-))))

Have fun!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::