8 “Hot” Valentine’s Day Ideas from the Thermal Processing Experts

/0 Comments/in Friday Afternoon /by Steve KowalskiWe know all about raising the temperature – something that happens around here day and night. Here are a few fun ideas and tips you can use to make the most of your Valentine’s Day and weekend.

1. Get Tickets to a Show – go online and look in your local area for fun show tickets. Check out local theater and what’s on the bill downtown. See if the matinee fits your schedule and make a day of it – go a bit early and enjoy the sights and sounds of the neighborhood.

2. Take A Long Walk – remember when you were dating and how much fun it was to walk holding hands. Bundle up and create a new route in your neighborhood. If it’s cold, like here in Cleveland, write your name in the snow and be sure to end up back in the kitchen for hot chocolate and marshmallows. Bring the kids along too and watch how much fun you’ll all have together.

3. Hide The Remote – may sound crazy, but declare a “no screens” night. No TV, computer or video games. Start a fire and just relax together. Talk about all the projects around the house that need to be done…don’t worry, by morning they will be forgotten.

4. Share A New Wine – set a budget and venture into the wine shop to try something new. Spend a little extra, and then head over to the grocery store to match it up with a simple light dinner and dessert. Light a candle and make it special.

5. Go Shopping Together – find a local store you both like and go shopping together. Set a budget, and split up to find something for your loved one. Check out separately, and wait until you get home to surprise one another. Save the receipt as you never know if your selection matches what your mate has in mind.

6. Build A Fire – there’s nothing like a nice fire to warm the house and help you relax. Pile on the firewood and get out the blanket. Spend time together just sitting. Perhaps a back rub is in order.

7. Text All Day – starting when you get up, send a text to your spouse (and kids) once an hour. Tell them just how special they are and have some fun. Send them on a scavenger hunt around the house with clues and remind them of the days when you first met.

8. Dinner & Dancing – remember when you were young how much fun you had dancing together. Pick up dinner on the way home and surprise your spouse. Dig out the old tapes and CD’s and play your favorites. If the kids are with you, make it a fun pizza night, and let them be the DJ – move away the furniture and boogie up a storm together – you’ll have a blast!

BONUS: Visit the Senior Center – have the kids make up handmade Valentine’s Day cards and buy some inexpensive candies. Head over to the center nearby and get permission to drop off Valentine’s Day goodie bags to the residents – watch their faces light up that someone took the time to make their day.

HARDENING OF ALLOY AND TOOL STEELS FOR IMPROVED PERFORMANCE

/0 Comments/in News, Technology, Uncategorized /by Steve KowalskiAt Kowalski Heat Treating (khtheat.com), we’re constantly working on behalf of our customers to achieve the proper balance of strength, durability and end performance when processing alloy and tool steels. This heat treatment process consists of heating and cooling these steels to move atoms to an atomic state called martensite.

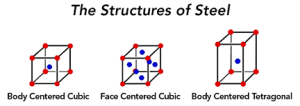

The atomic arrangement of steels vary depending on the structure or phase it is in. Controlled heat treatment changes the arrangement of these atoms resulting in a desired hardness and mechanical properties specified by our customers. Often we customize this process to enhance tool life and durability.

“Tool steels are typically annealed after rolling or forming to make them suitable for machining and other operations, a process which consists of heating the steel slowly and uniformly to a temperature above the transformation range,” says Dave Lorenz, VP of Operations / Metallurgist at Kowalski Heat Treating. “The transformation range is the temperature at which the steel starts to form austenite, usually around 1350°F (the annealing temperature is 1600-1700°F). A slow cooling rate (25 – 40°F/hour maximum) from this temperature enables the alloys, in combination with the iron atoms, to form uniformly dispersed spheroidized carbides in a matrix of ferrite. This ferrite structure is a body-centered cubic structure (see graphic), typically the condition in which we receive steel tool grades unless they are pre-hardened by the customer.”

“To achieve the next phase, the tool steel is hardened by bringing the material up to its austenitizing temperature, which will range from 1500 – 2250°F depending on the grade,” said Dave. “Upon going through this transformation temperature range, the structure changes again – from ferrite to austenite. This austenite atomic structure is a face-centered cubic (see graphic) – a high temperature phase only formed by heating the tool steel to the appropriate temperature. Austenite is non-magnetic and is slightly denser than ferrite, causing the steel to shrink slightly when at this stage in heat treatment.”

“Upon cooling or quenching from the austenitizing temperature, the steel is transformed once again into a new atomic arrangement called martensite. The steel must be cooled fast enough to keep the dissolved alloy content in the matrix of the steel. The martensite is in the form of a body centered tetragonal structure (see chart) – the desired structure that most of our tool steels are in to achieve high hardness and strength properties. This arrangement of atoms is less dense which results in an overall growth after the quench and subsequent tempers.”

Once completed, the tool steel is shipped back to customers to be machined or sharpened for superior performance.

For more information on tool steel processing, contact Kowalski Heat Treating (khtheat.com) – the leader in distortion sensitive thermal processing, celebrating 40 years of excellence and customer service.