40 Percent

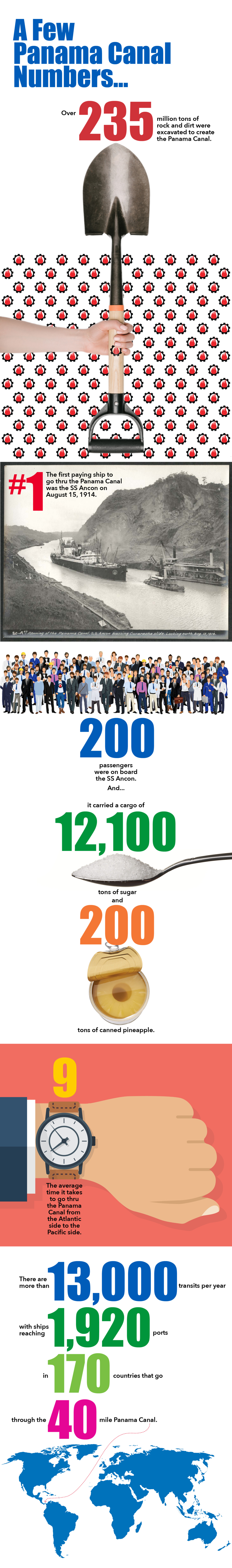

Being a manufacturing geek, and lover of working on and solving PIA (Pain in the @%$) Jobs! I got to thinking about all the products that move about the world, especially shipping vessels afloat. With the high-volume straits in the news, I went online and tried to get a handle on volume, time travel on the water, and “who ships what where”. Something I didn’t know is that the US is the largest user of the Panama Canal – yep, about 40 percent of the traffic. I did some history digging and found some cool history – with US construction beginning on May 4th, 1904. Clearly, the construction of the Panama Canal was a monumental engineering achievement that’s had a significant impact on global trade and transportation. To this day, the Panama Canal stands as a testament to human ingenuity and engineering prowess, playing a crucial role in global maritime trade and navigation. All of us need to realize that this was construction with 1920’s technology! Special thanks to history.com and Wikipedia.com.

There’s more…read on!

- The idea of creating a water passage across the isthmus of Panama to link the Atlantic and Pacific Oceans dates back to at least the 1500s: After explorer Vasco Nuñez de Balboa realized that a narrow strip of land separated the two oceans, King Charles I of Spain tapped his regional governor to survey a route along the Chagres River.

- The realization of such a route across the mountainous, tropical terrain was deemed impossible at the time, although the idea remained tantalizing as a potential shortcut from Europe to eastern Asia. The only other route was to sail around South America via the stormy, unpredictable Strait of Magellan, or use the Panama Railroad to transfer goods and people from one ocean to another.

- France was ultimately the first country to attempt the task. Led by Count Ferdinand de Lesseps, the builder of the Suez Canal in Egypt, the construction team broke ground on a planned sea-level canal in 1880.

- The French quickly comprehended the monumental challenge ahead of them: Along with the incessant rains that caused heavy landslides, there was no effective means for combating the spread of yellow fever and malaria. De Lesseps belatedly realized that a sea-level canal was too difficult and reorganized efforts toward a lock canal, but funding was pulled from the project in 1888. Following the deliberations of the U.S. Isthmian Canal Commission and a push from President Theodore Roosevelt, the United States purchased the French assets in the canal zone for $40 million in 1902. When a proposed treaty over rights to build in what was then a Colombian territory was rejected, the U.S. threw its military weight behind a Panamanian independence movement, eventually negotiating a deal with the new government.

- On November 6, 1903, the United States recognized the Republic of Panama, and on November 18 the Hay-Bunau-Varilla Treaty was signed with Panama, granting America exclusive and permanent possession of the Panama Canal Zone. In exchange, Panama received $10 million and an annuity of $250,000 beginning nine years later. The treaty, negotiated by U.S. Secretary of State John Hay and French engineer Philippe-Jean Bunau-Varilla, was condemned by many Panamanians as an infringement on their country’s new national sovereignty.

- Seemingly not grasping the lessons from the French effort, the Americans devised plans for a sea-level canal along the roughly 50-mile stretch from Colón to Panama City. The project officially commenced with a dedication ceremony on May 4, 1904, but chief engineer John Wallace encountered immediate problems. Much of the French equipment was in need of repair, while the spread of yellow fever and malaria was frightening off the workforce. Under pressure to keep construction moving forward, Wallace instead resigned after a year.

- A railroad specialist named John Stevens took over as chief engineer in July 1905 and immediately addressed the workforce issues by recruiting West Indian laborers. Stevens ordered new equipment and devised efficient methods to speed up work, such as the use of a swinging boom to lift chunks of railroad track and adjust the train route for carting away excavated material. He also quickly recognized the difficulties posed by landslides and convinced Roosevelt that a lock canal was best for the terrain.

- The project was helped immensely by chief sanitary officer Dr. William Gorgas, who believed that mosquitoes carried the deadly diseases indigenous to the area. Gorgas embarked on a mission to wipe out the carriers, his team painstakingly fumigating homes and cleansing pools of water. The last reported case of yellow fever on the isthmus came in November 1905, while malaria cases dropped precipitously over the following decade.

- Although construction was on track when President Roosevelt visited the area in November 1906, the project suffered a setback when Stevens suddenly resigned a few months later. Incensed, Roosevelt named Army Corps engineer Lt. Col. George Washington Goethals the new chief engineer, granting him authority over virtually all administrative matters in the building zone. Goethals proved a no-nonsense commander by squashing a work strike after taking charge, but he also oversaw the addition of facilities to improve the quality of life for workers and their families.

- Goethals focused efforts on Culebra Cut, the clearing of the mountain range between Gamboa and Pedro Miguel. Excavation of the nearly 9-mile stretch became an around-the-clock operation, with up to 6,000 men contributing at any one time. Despite the attention paid to this phase of the project, Culebra Cut was a notorious danger zone, as casualties mounted from unpredictable landslides and dynamite explosions.

- Construction of the locks began with the pouring of concrete at Gatún in August 1909. Built in pairs, with each chamber measuring 110 feet wide by 1,000 feet long, the locks were embedded with culverts that leveraged gravity to raise and lower water levels. Ultimately, the three locks along the canal route lifted ships 85 feet above sea level, to man-made Gatún Lake in the middle. Hollow, buoyant lock gates were also built, varying in height from 47 to 82 feet. The entire enterprise was powered by electricity and run through a control board.

- The grand project began drawing to a close in 1913. Two steam shovels working from opposite directions met in the center of Culebra Cut in May, and a few weeks later, the last spillway at Gatún Dam was closed to allow the lake to swell to its full height. In October, President Woodrow Wilson operated a telegraph at the White House that triggered the explosion of Gamboa dike, flooding the final stretch of dry passageway at Culebra Cut.

- The Panama Canal officially opened on August 15, 1914, although the planned grand ceremony was downgraded due to the outbreak of WWI. Completed at a cost of more than $350 million, it was the most expensive construction project in U.S. history to that point.

- Altogether, some 3.4 million cubic meters of concrete went into building the locks, and nearly 240 million cubic yards of rock and dirt were excavated during the American construction phase. Many people, however, died building the Panama Canal: Of the 56,000 workers employed between 1904 and 1913, roughly 5,600 were reportedly killed, though the actual number is probably much higher, since the French only recorded deaths that occurred in hospital.

- Bolstered by the addition of Madden Dam in 1935, the Panama Canal proved a vital component to expanding global trade routes in the 20th century. The transition to local oversight began with a 1977 treaty signed by U.S. President Jimmy Carter and Panama leader Omar Torrijos, with the Panama Canal Authority assuming full control on December 31, 1999.

Recognized by the American Society of Civil Engineers as one of the seven wonders of the modern world in 1994, the canal hosted its 1 millionth passing ship in September 2010. On average about 14,000 ships transfer through the canal each year (that means, since 2010, about 175,000 ships have pass through – that’s crazy!!)

Long story video from Modern Marvels: CLICK HERE

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

DO YOU LIKE CONTESTS?

Me, too.

As you may know the Kowalski Heat Treating logo finds its way

into the visuals of my Friday posts.

I. Love. My. Logo.

One week there could be three logos.

The next week there could be 15 logos.

And sometimes the logo is very small or just a partial logo showing.

But there are always logos in some of the pictures.

So, I challenge you, my beloved readers, to count them and send me a

quick email with the total number of logos in the Friday post.

On the following Tuesday I’ll pick a winner from the correct answers

and send that lucky person some great KHT swag.

So, start counting and good luck!

Oh, and the logos at the very top header don’t count.

Got it? Good. :-))))

Have fun!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

Leave a Reply

Want to join the discussion?Feel free to contribute!