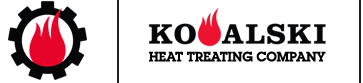

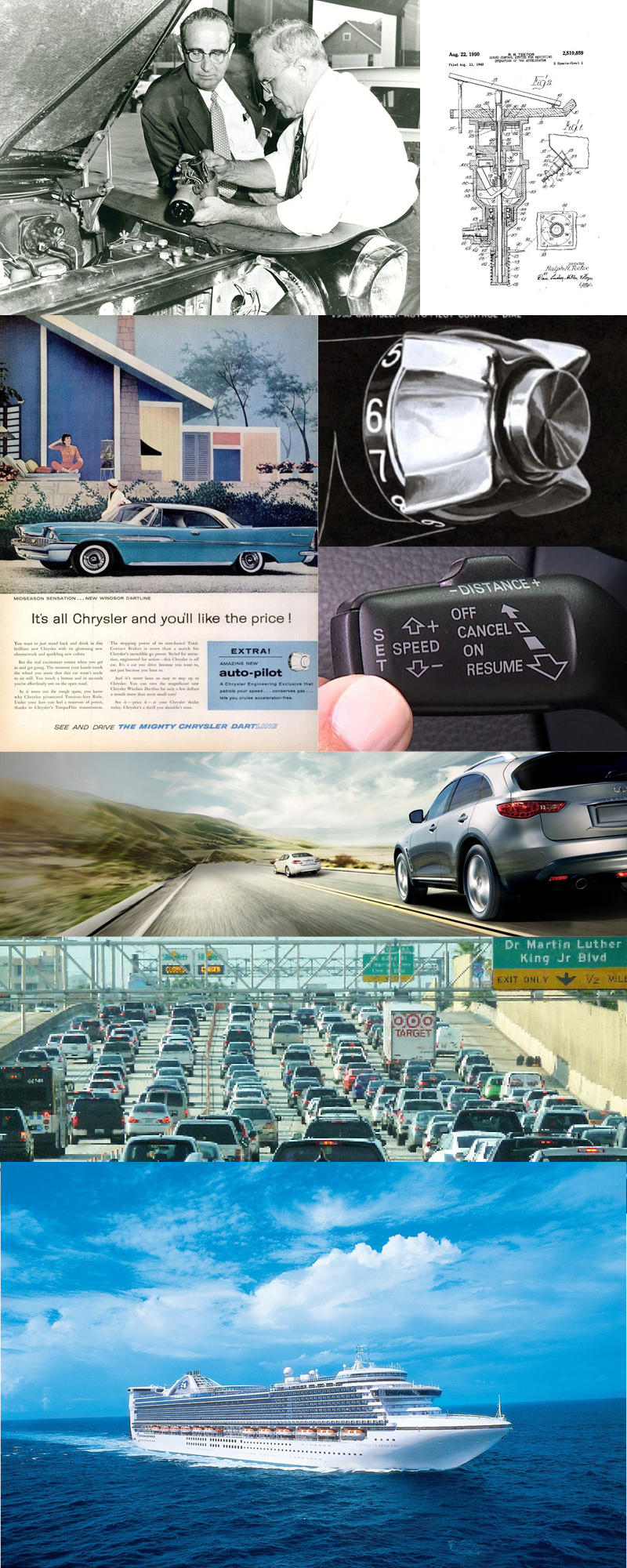

The U.S. Army Corps of Engineers are amazing. Just a few of their important projects:

1. New Orleans flood protection system

2. The Lincoln Memorial

3. The great lakes restoration project

4. The Pentagon

5. ICBM Silos

6. WWII – D-Day They made the landing happen

7. Cape Kennedy vehicle assembly building

8. The Library of Congress

9. The St. Lawrence Seaway

10. Hundreds and hundreds of other of other amazing waterway projects most of us take for granted

Of all the Corps has done, this project to protect New Orleans since the catastrophic flooding from Hurricane Katrina is a real engineering marvel!!!

Ever take the time to reflect on some of the “really” big projects that have been built in Ohio and in our country. Giant dams, long waterways, canals and harbors and so much more. Recently, I read an article about some really exciting projects coming to our beautiful “North Coast” – after years and years of talking, multiple groups will begin re-engineering some really great stuff (one idea is to create an island off the coast). On this day, March 11, 1779, Congress established the U.S. Army Corps of Engineers to help plan, design and prepare environmental and structural facilities for the U.S. Army, made up of civilian workers, members of the Continental Army and French officers. For nearly 250 years, they have tackled some amazing works (talk about PIA (Pain in the @%$) Jobs!). We salute all of those engineers, technicians, scientists and “hard workin’ guys and gals who helped shape our nation. Here’s some lengthy (but great) history, videos and tidbits I think you’ll enjoy. We salute you! Special thanks to historychannel.org, fpri.org, Wikipedia.org, ranker.com and YouTube for the info and videos. Love it!

The members of the Corps who had joined at the time of its founding in 1779 left the army with their fellow veterans at the end of the War for Independence. In 1794, Congress created a Corps of Artillerists and Engineers to serve the same purpose under the new federal government. The Corps of Engineers itself was reestablished as an enduring division of the federal government in 1802.

The U.S. Army Corps of Engineers is America’s oldest and largest engineering organization, and at times, the most controversial. Since 1802, when Congress created the Corps within the U.S. Military Academy at West Point, the army engineers have brought science into government and extended the federal responsibility for natural resources.

As the construction arm of Congress, the engineers managed some of the world’s most monumental construction, as the nation’s premier builders of water projects-dams, dikes, canals, harbors, hydro facilities, and navigation channels. Visit HERE for some of the “big” projects.

Both “Beast” and “Benefactor” the Corps is praised as a nation builder, elsewhere denounced as an out-of-control bulldozer. Following a “bigger-is-better” national ethos, the Corps had been grandiose and also at odds with American traditions. In a nation committed to private enterprise and states’ rights, the Corps has been denounced as a military agent of big-government centralization.

The Corps emerged from the formative conflicts that divided the young republic during the Federalist Era. George Washington’s America stood at a geopolitical crossroads between two great rivals in Europe: Britain and France. Britain was the great center of industrial capitalism. Its grandest construction projects were built by self-made private enterprise. France was the center of science and formal academic training. France’s most magnificent projects were tax-financed and military inspired.

Hamilton advanced the idea that roads, canals, and other public construction were necessary for public safety. The Constitution, said Hamilton, implied a federal authority to build lighthouses for the safety of shipping, to remove obstructions to river commerce, and to build highways for troops. Thomas Jefferson, although suspicious of bureaucracy, admired the French talent for comprehensive planning and scientific professionalism. The result was a so-called “mixed enterprise” that allowed Congress to purchase stock and otherwise subsidize local construction. Jefferson envisioned a military academy for engineers that would professionalize the army and coordinate public works.

French engineering inspired the Corps. At the U.S. Military Academy, an engineering school, West Pointers learned French, studied mathematics, and grounded engineering in theory. French schooling left the West Pointers with an attraction to federally funded networks of projects and a preference for complex design. In 1816, President James Madison recruited French general Simon Bernard to head a U.S. board of fortification planners. The Monroe administration expanded Bernard’s authority to roads and canals.

After 1824, with the passage of the General Survey Act and the first federal river improvement act, the French-led Corps of Engineers assumed an active role as transportation planners. Together with the U.S. Bureau of Topographical Engineers, the Corps planned lighthouses, bridges, and Great Lakes ports of refuge from Buffalo to Duluth and our French-trained army engineers pioneered urban planning and sanitation engineering in Washington, D.C.

Many times, Congress hotly debated the constitutionality of federal internal improvements, the most expensive federal projects were seacoast fortifications. From 1808 to 1861, army engineers built one of the world’s most sophisticated systems of fortified harbors-more than 50 massive projects. Army engineers also surveyed the competing routes for the Pacific Railroad. Only about 100 strong, the engineering elite of the army planned a dozen major canals, a national highway, hundreds of beach-front dikes, and thousands of miles of navigation channels.

Gradually the Corps also took responsibility for planning a system of flood levees on the Lower Mississippi. After 1902, civilian agencies such as the U.S. Geological Survey and the dam-building U.S. Reclamation Service rose to challenge the Corps monopoly over monumental construction. But the Corps, still the favorite of Congress, remained the nation’s foremost authority on water construction. Broad powers of implementation allowed the engineers to broker public assistance and direct federal aid.

Three missions have since dominated the Corps civil works. The first is navigation improvement-the channeling of rivers, the dredging of harbors, and the construction of locks and dams. For example, Corps-built navigation channels move oil from Tulsa to refineries above New Orleans. Barges of wheat and corn lock through Army engineered rivers from Omaha to Chicago. Soo Locks allow ships to travel between Lake Superior and the lower Great Lakes. The Corps’s Saint Lawrence Seaway connects the North Atlantic to the Great Lakes and the Mississippi tows push river barges through the Corps’s slackwater staircase from St. Louis to St. Paul. LINK

A second mission is flood control. This mission began in 1850 when a flood on the Mississippi excited the attention of Congress. After 1879, with the creation of the Corps-led Mississippi River Commission, engineers developed a sophisticated science of floodway design. In 1917, after another bad flood year on the Mississippi, Congress turned again to the Corps. On the Mississippi River and Sacramento River. In 1936, Congress expanded the federal flood program to the 48 states with $310 million for 250 projects.

The grandest result of the program was the Mississippi River and Tributaries project-the MR&T. Its vast system of levees and spillways funnels the dangerous river from St. Louis to New Orleans. Link to how the levees have been expanded by the Corps after the New Orleans disaster in the early 2000’s

A third mission grew from the same scientific tradition that made the Corps an expert on floods. Corps engineers led the scientific surveys that mapped water resources. The engineers also surveyed Yellowstone and Yosemite parks.

In 1899, the so-called Refuse Act extended the environmental mission, making the engineers responsible for obstructions in navigable streams. Here began the Corps’s controversial permit authority to regulate dumping. Legislation such as the 1972 and 1974 Clean Water Acts expanded that authority. With the rise of the environmental movement, and the passage of the National Environmental Policy Act in 1969, the Corps became the steward of fraying coastlines and vanishing swamps.

Like so many decisions in our history – The Corps-for better or for worse-has been the agent of this modernization, as Americans have learned that every engineering solution always has secondary consequences. For example, – Should we actually be building multi-million dollar homes over and over again on beaches and expecting a different outcome from major storms / hurricanes, and flooding?

Great Lakes and Ohio Valley Projects

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

DO YOU LIKE CONTESTS?

Me, too.

As you may know the Kowalski Heat Treating logo finds its way

into the visuals of my Friday posts.

I. Love. My. Logo.

One week there could be three logos.

The next week there could be 15 logos.

And sometimes the logo is very small or just a partial logo showing.

But there are always logos in some of the pictures.

So, I challenge you, my beloved readers, to count them and send me a

quick email with the total number of logos in the Friday post.

On the following Tuesday I’ll pick a winner from the correct answers

and send that lucky person some great KHT swag.

So, start counting and good luck!

Oh, and the logos at the very top header don’t count.

Got it? Good. :-))))

Have fun!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::