Creamy Goodness

Soft serve ice cream is one of my favorite ice creams. Actually, I never met an ice cream I didn’t like. And I found on Google that there is no shortage of t-shirts and hats to show just how much ice cream means to you. :))))

The things we often take for granted. The car starts and runs. The lights go on when you flip a switch. The televisions, radios and computers just run, and run and run. My phone connects to the internet and downloads in milliseconds. The washing machine cleans the clothes, and the dryer does its thing too. I could go on. But one invention that I’m a BIG fan of is soft ice cream. Now, I’ll take any type of ice cream for sure – hard scoops of goodness from Mitchell’s or Malley’s here in Cleveland. Lemon ice after a meal – especially when added to my favorite potent beverage! But sometimes, when the moment is right, I’m just in the mood for soft ice cream served in a cone. Like you, I pause – sugar cone or traditional or in a cup. Then comes the toppings (I must say Dairy Queen rocks here – hard shell dip, sprinkle dinkels (brilliant name) a little fudge and peanuts or just plain. To compound decisions, some offer a “twist” of chocolate and vanilla – brilliant! As a kid, we’d race on our bikes to meet the Mr. Softie ice cream truck in the neighborhood- I can still remember that music. And then pass over our pocket full of change, after watching the magic twirl above the cone. Our girls will tell you while trying not to laugh how Jackie would offer to help them “clean” the soft serve cones so they wouldn’t get messy when they were very young! She is continuing this tradition with our grandkids! Yesterday was Soft Ice Cream Day, so I just had to get some trivia and share. Click on the music link and enjoy the read. And thanks to You Tube, Wikipedia and answers.com.

Mister Softee Ice Cream Truck Theme

Dog is crazy about Eddie the ice cream man

Soft serve, also known as soft ice, is a frozen dairy dessert, similar to ice cream but softer and less dense as a result of air being introduced during freezing.

Soft serve is generally lower in milkfat (3 to 6 percent) than ice cream (10 to 18 percent) and is produced at a temperature of about −4 °C (25 °F) compared to ice cream, which is stored at −15 °C (5 °F). Soft serve contains air, introduced at the time of freezing. The air content, called overrun, can vary from 0 to 60 percent of the total volume of the finished product. The amount of air alters the taste of the finished product.

Products with low quantities of air has a heavy, icy taste and appears more yellow. Ice cream with higher air content tastes creamier, smoother, and lighter and appears whiter. The optimum quantity of air is determined by other ingredients, if any, and individual taste. It is generally accepted that the ideal air content should be between 33 and 45 percent of volume. If more than this, the product loses taste, tends to shrink as it loses air, and melts more quickly than that with less air. Less than 33 to 45 percent, the product will not melt as quickly but will not taste good.

All ice cream must be frozen quickly to avoid crystal growth. With soft serve, this is accomplished by a special machine at the point of sale. Pre-mixed product is introduced to the storage chamber of the machine where it is kept at 3 °C (37 °F). When the product is drawn from the draw valve, fresh mix combined with the targeted quantity of air is introduced to the freezing chamber either by gravity or pump. It is then churned and quickly frozen and stored until required.

While some machines only dispense one flavor of the mix at a time, certain models of soft-serve machines have an additional nozzle that dispenses a mixture of two separate flavors simultaneously. This mixture emerges in a distinct swirl pattern. It is classified as its own separate flavor on menus as swirl or twist.

In the US, soft serve is not sold prepackaged in supermarkets, but is common at fairs, carnivals, amusement parks, restaurants (especially fast food and buffet), and specialty shops. All ice cream must be frozen quickly to avoid crystal growth. With soft serve, this is accomplished by a special machine that holds pre-mixed product at a very low, but not frozen, temperature at the point of sale.

Charles Taylor of Buffalo, New York patented an automatic ice cream maker in 1926 that is reported to be the first soft serve ice cream machine. His Taylor Company continues to manufacture the McDonald’s ice cream machine.

Over Memorial Day weekend of 1934, Tom Carvel, the founder of the Carvel brand and franchise, suffered a flat tire in his ice cream truck in Hartsdale, New York. He pulled into a parking lot and began selling his melting ice cream to vacationers driving by. Within two days he had sold his entire supply of ice cream and concluded that both a fixed location and soft (as opposed to hard) frozen desserts were potentially good business ideas. In 1936, Carvel opened his first store on the original broken down truck site and developed a secret soft serve ice cream formula as well as patented super low-temperature ice cream machines.

Dairy Queen also claims to have invented soft serve. In 1938, near Moline, Illinois, J. F. McCullough and his son, Alex, developed their soft serve formula. Their first sales experiment was August 4, 1938, in Kankakee, Illinois, at the store of their friend, Sherb Noble. Within two hours of the “all you can eat” trial sale, they had dished out more than 1,600 servings—more than once every 4.5 seconds.

The Tin roof sundae (or hot tin roof) was a version of the Cherry sundae sold by Chester Platt in 1893. Platt’s soda fountain in Ithaca New York was popular at the time and several area fountains added various toppings. Chocolate syrup and peanuts made up the “TIN ROOF” topping based on the original sound of the peanuts being removed from the cans in which they were sold, like the sound of rain on a tin roof.

It is a common myth that during the late 1940s, future UK prime minister Margaret Thatcher worked briefly as a chemist for food manufacturer J. Lyons and Co., at a time when the company had partnered with the United States distributor Mister Softie and was developing a soft-serve recipe that was compatible with the American machines. Thatcher’s precise role at Lyons is unclear, but she is reported to have worked on the quality of cake and pie fillings as well as ice-cream and researched saponification. (never thought of her as a “softie”).

The US produces about 6.4 billion pounds of ice cream treats a year. #1 flavor – vanilla.

The average American eats 23 pounds of ice cream a year – (and many carry it around with them afterwards).

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

DO YOU LIKE CONTESTS?

Me, too.

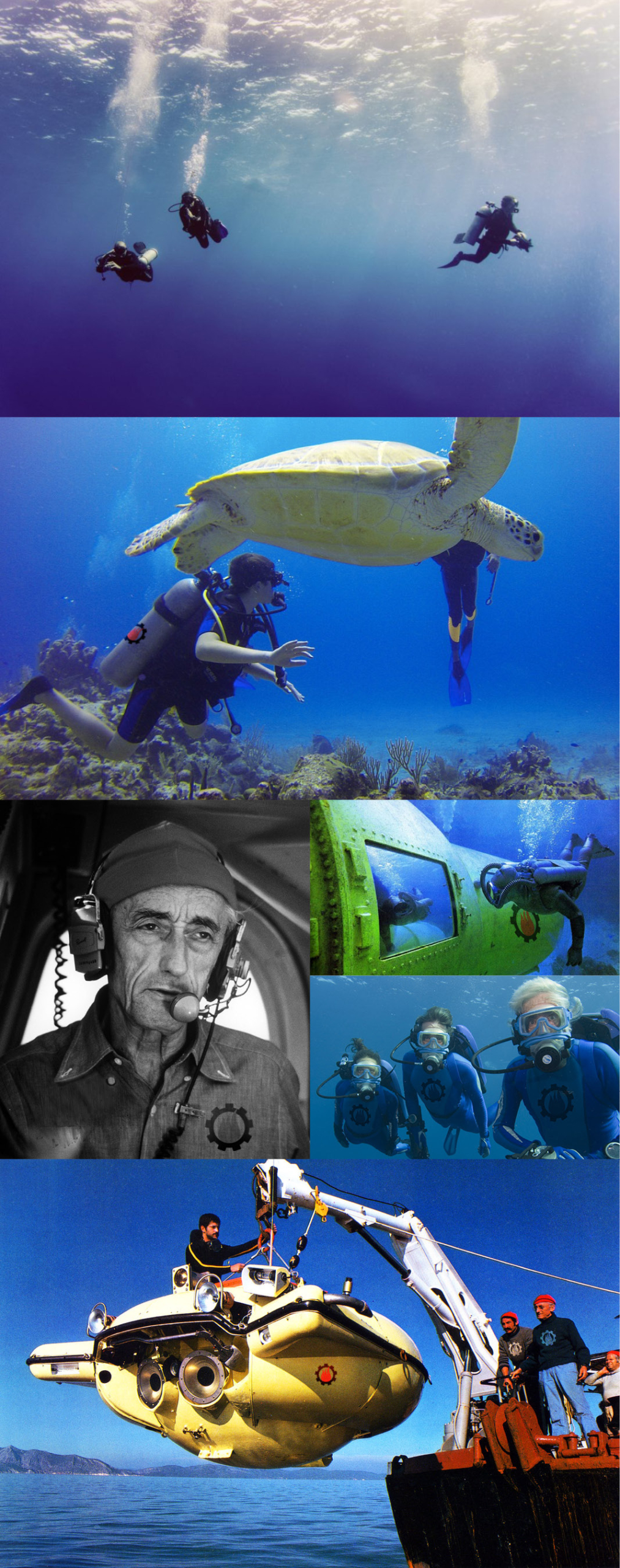

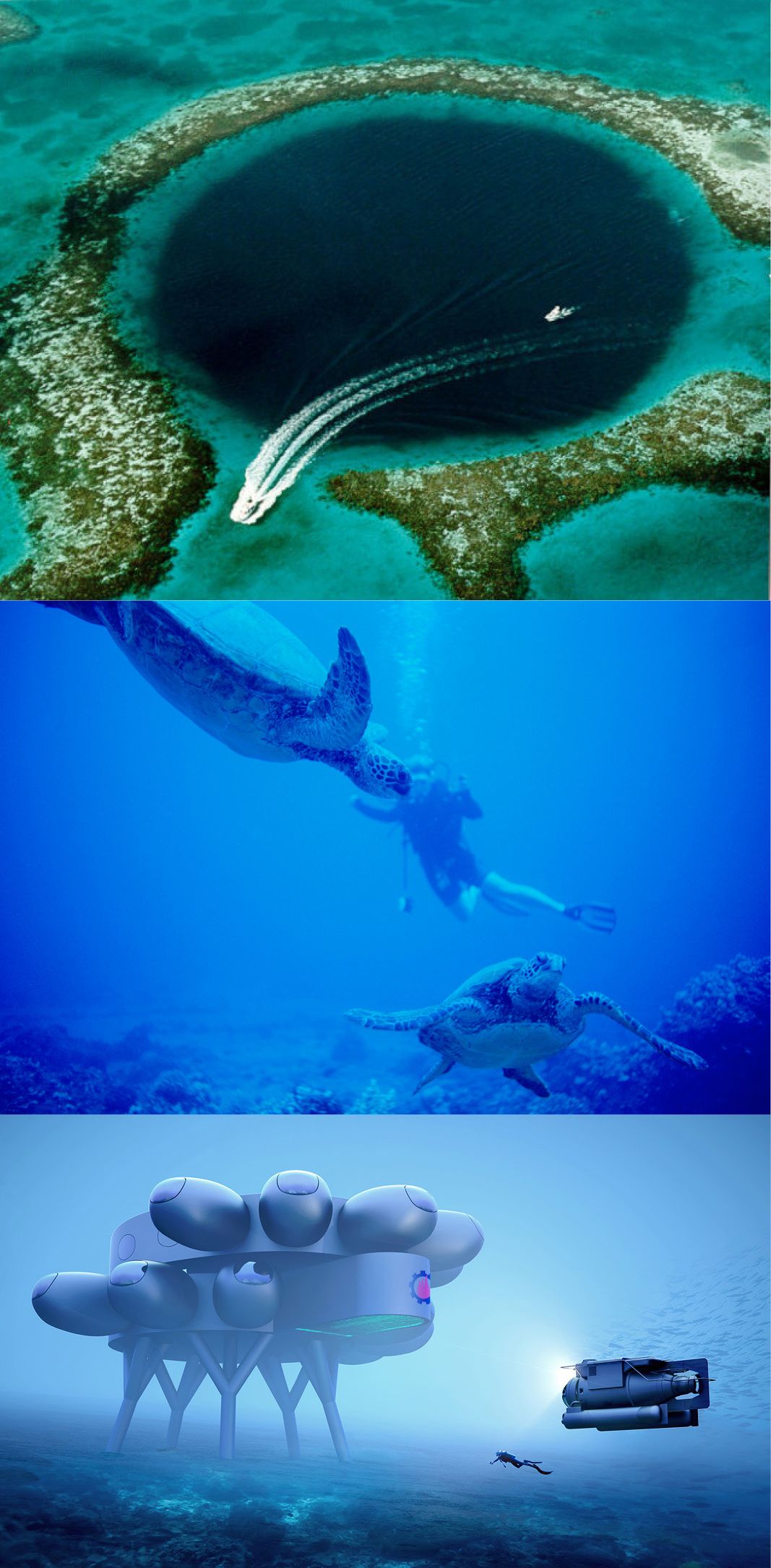

As you may know the Kowalski Heat Treating logo finds its way

into the visuals of my Friday posts.

I. Love. My. Logo.

One week there could be three logos.

The next week there could be 15 logos.

And sometimes the logo is very small or just a partial logo showing.

But there are always logos in some of the pictures.

So, I challenge you, my beloved readers, to count them and send me a

quick email with the total number of logos in the Friday post.

On the following Tuesday I’ll pick a winner from the correct answers

and send that lucky person some great KHT swag.

So, start counting and good luck!

Oh, and the logos at the very top header don’t count.

Got it? Good. :-))))

Have fun!!

::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::